The use of load cells within product manufacturing has seen a shift in emphasis from unit cost considerations alone back towards weighing performance.

The use of load cells within product manufacturing has seen a shift in emphasis from unit cost considerations alone back towards weighing performance. Multiple factors have brought about this recent change, like precision batch process automation requirements, material accountability, process yield reporting, and ISO9000 and FDA certification requirements. Properly evaluating a weighing system’s performance all starts with the design of a system’s fundamental components, the stress measurement member, typically referred to as the “load cell,” and the correct mounting hardware. To learn more about precision load cells, what they measure, and how they affect weighing and batching, read on!

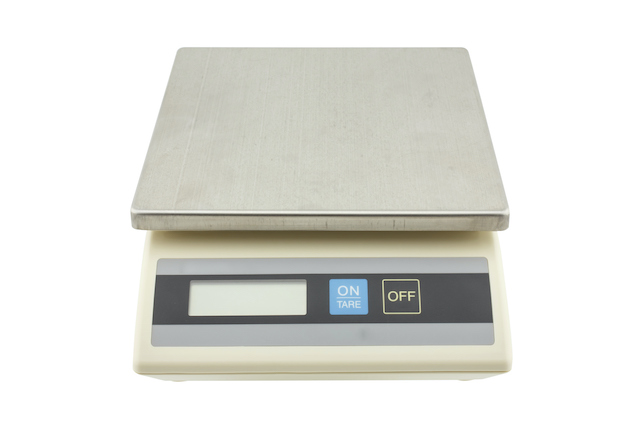

How the Load Cells Work

All industrial load cells share common design principles when using strain gauges to measure the deflection or deformation of an aluminum or steel structure. By using this type of technology, load cell works basically as a force-measuring device in your lab. Taking this into account means that any kind of force which is transferred to your load cell will influence the strain gauge. The expectation of a load cell is to get a signal that is proportional to the applied load (which is force = mass x gravity) under dynamic process conditions. The following measurable factors are influential to all load cells and ultimately to the absolute in-process measurement output accuracy too. It is very essential to bear in mind that load cells measure applied force. The measurable factors include:

Hysteresis

This is the maximum difference between the load cells loading output and the unloading output, starting from zero to nominal rated capacity and then back to zero.

Non-Linearity

This is the maximum deviation from the best straight line from no load to rated output.

Repeatability

This is the difference between load cell output readings taken from any consecutive tests under identical nominal loading and environmental conditions.

Creep

Creep refers to the change in load cell output occurring with time while under constant load and with environmental conditions and other variables all remaining consistent.

Zero Signal Temperature Coefficient

This is the relative output signal variation without load involved.

Rated Output Temperature Coefficient

Finally, this is the relative variation of the real rated output sensitivity.

In order to accurately compare load cell performance, every one of these factors have to be taken into consideration. The combination of all of these potential errors can be minimized by using proper alloys, correct design of strain gauges to fit the mechanical structures, precision machining practices, special material heat treatments, and hardening processes, having very reliable manufacturing processes. To learn more about load cells and how they work in your laboratory, give us a call!

FOR ALL ISO 17025 CALIBRATION SERVICES, CONTACT LAB PEOPLE TODAY

The Lab People Inc. is a trusted provider of laboratory equipment, services, supplies, and rental equipment for you and your laboratory. As an ISO 17025 accredited service organization, we stand behind our services with 100% satisfaction guaranteed for all of our customers. We offer calibration services for balances, pipettes, moisture analyzers, force measurement, test weights and more. Services include preventative maintenance, SQ-Min, IQOQ, repairs, legal for trace/placed in service, verification and more.

For more information about how we can assist you, visit our website, email us, or give us a call at 1-800-296-2001!

Do not forget to follow us on Facebook, Twitter, and Linkedin!