How often should you have the material tester fully calibrated, and who should be the one to perform the calibration?

If you have spent a lot of money on a high-quality material tester that meets all of your testing needs, then you expect it to last a very long time. When purchased, it comes with a newly calibrated load cell, so you can feel very confident that the measurements are all accurate. However, how accurate are these measurements after a year? Or two years even? How often should you have the material tester fully calibrated, and who should be the one to perform the calibration so that you’re guaranteed the very best results? Read on to learn why calibrating your materials tester is so important!

What Makes Calibration So Important?

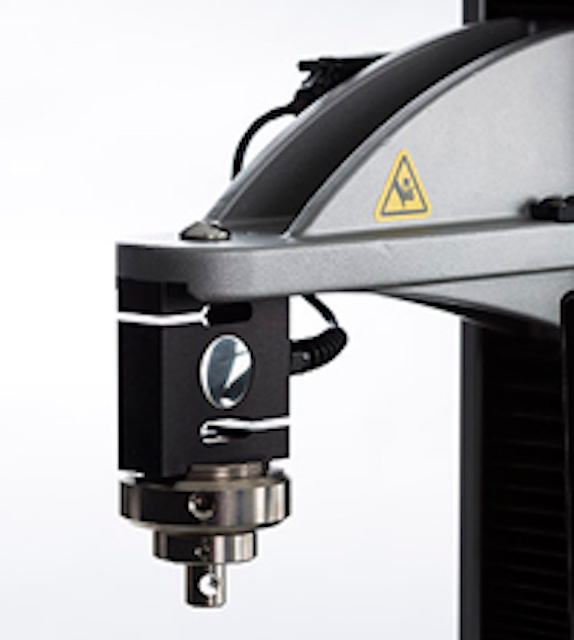

When you’ve purchased your material tester, the tester and load cell will be calibrated and verified during the manufacturing process and shipped to final destination. It is recommended that setup occurs by a manufacturer-accredited Service Technician as a part of the entire installation and verification process. After the initial install, you can be reassured that you’ve got a material tester that is ready to use, that is performing at its best, and giving accurate material testing results for your products.

However, the material tester could become less precise in its measurements over time because of external influences. Perhaps you suddenly notice that you’re not getting the test results you expected, or maybe you never noticed the tiny inaccuracies in the measurements. However, the measurements have an impact on your product quality, and ultimately your lab partners may notice a a slight difference in the quality of your products before you find out that something has gone wrong. This scenario can get expensive for your laboratory’s finances and its reputation too. This is why maintaining a calibration cycle of your test stand and load cells is important.

How Often Should You Calibrate the Material Tester?

An accredited calibration certificate is valid for up to a year, so to make sure that your material tester meets the calibration requirements and to maintain continuously accurately measures, your lab should undertake an annual calibration. An annual calibration of the material tester helps ensure that smaller inaccuracies that might occur in your material testers measurements (height, speed and weight) are detected right before the inaccuracies become more prominent over time and have a serious impact on the overall quality of the product and, in certain cases, the safety of the products too.

Who Could Calibrate the Material Tester?

The Scale and Lab People offer ISO 17025 on-site and off-site calibration of material testers, force gauges, and load cells. We offer annual preventative maintenance plans for maintaining your equipment. Our sales team can also offer replacement equipment for old or broken units. For new applications, we can help customers with new units that will fit their labs needs.

FOR ALL LAB EQUIPMENT AND LAB NEEDS, CONTACT LAB PEOPLE TODAY

The Lab People Inc. is a trusted provider of laboratory equipment, services, supplies, and rental equipment for you and your laboratory. As an ISO 17025 accredited service organization, we stand behind our services with 100% satisfaction guaranteed for all of our customers. We are here to provide you with the best lab equipment service, equipment, and supplies.

For more information about how we can assist you, visit our website, email us, or give us a call at 1-800-296-2001!

Do not forget to follow us on Facebook, Twitter, and Linkedin!