Different standardized tests have to be conducted to measure the content of any active substances, uniformity of content, disintegration time, and the dissolution and uniformity of weight.

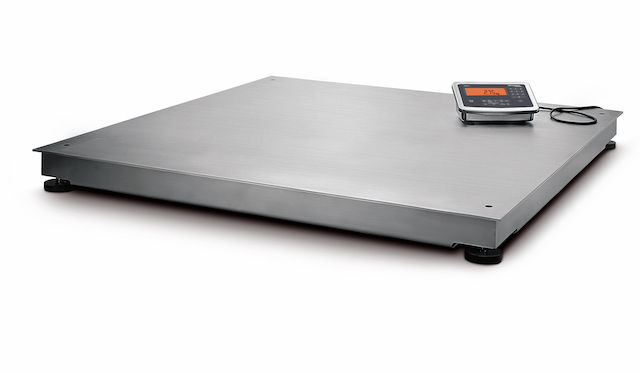

Different standardized tests have to be conducted to measure the content of any active substances, uniformity of content, disintegration time, and the dissolution and uniformity of weight. These tests help determine the active substances’ content and in vitro release. The test for the uniformity of weight is performed by individually weighing tablets, and capsules randomly picked from a batch and determining their weight.

Cubis II MCA balances with a tablet feeder and some QApp tablet checks offer a convenient solution to investigate tablets and capsules by Pharmacopoeia. Users with the role of creating some tasks are allowed to develop newer products and set product parameters too. For the product to be tested, the product kind, nominal weight, minimum lower and upper tolerance, and maximum lower and upper tolerance and plausibility must be defined.

The Cubis Weight-Checking Process

If inactivated, the results are then calculated by using some fixed tolerances. With the dynamic tolerance switched on, some permissible limits are calculated based either on the mean value recalculated after every sample measurement or the average mean value after measuring every sample. Furthermore, a plausibility value is set up to identify estimated sample weights out of a plausible range. Out-of-plausibility samples are excluded from any results calculation.

The user sets up the number of samples during the test procedure. If tablets are measured, pieces are placed one after another onto the balance manually by the user or automatically by some connected tablet feeder until the specified number of pieces is measured out. For capsules, first, the average mean weight value of empty capsules is determined or entered by the user.

Result Evaluation

A tolerance bar is displayed if the results are evaluated using fixed tolerances or other dynamic tolerances with recalculation after every sample. If the measured sample weight is within the set lower and upper minimum permissible limit of the tolerance bar is then shown in green; if the weight is between the minimum and maximum tolerance, the tolerance bar will then switch yellow, and for samples, weights out of both limits, red will be the color displayed in the tolerance bar. By the color code, the operator will get visual feedback during the measurement for every sample.

FOR ALL ISO 17025 CALIBRATION SERVICES, CONTACT LAB PEOPLE TODAY

Lab People Inc. is a trusted provider of laboratory equipment, services, supplies, and rental equipment for you and your laboratory. As an ISO 17025 accredited service organization, we stand behind our services with 100% satisfaction guaranteed for all our customers. We offer on-site and off-site calibration services for balances, pipettes, moisture analyzers, force measurement, test weights, and more. Services include preventative maintenance, SQ-Min, IQOQ, repairs, legal for trace/placed in service, verification, and more.

For more information about how we can assist you, visit our website, email us, or call us at 1-800-296-2001!

Do not forget to follow us on Facebook, Twitter, and Linkedin!